Thermoforming is one of the most efficient and versatile plastic manufacturing processes available today. It involves heating a plastic sheet until it becomes pliable, shaping it over a mold, and then cooling it into a durable, finished product.

This simple yet powerful process allows manufacturers to create everything from lightweight packaging solutions to complex, custom-designed components. Because thermoforming offers exceptional precision, flexibility, and cost-effectiveness, it has become a preferred choice for producing plastic blisters, clamshells, trays, and more.

As a leading plastic thermoformer, Munot Plastics is here to explain everything you need to know about what thermoforming is, how it works, and why it’s the best solution for packaging that protects, showcases, and enhances your product.

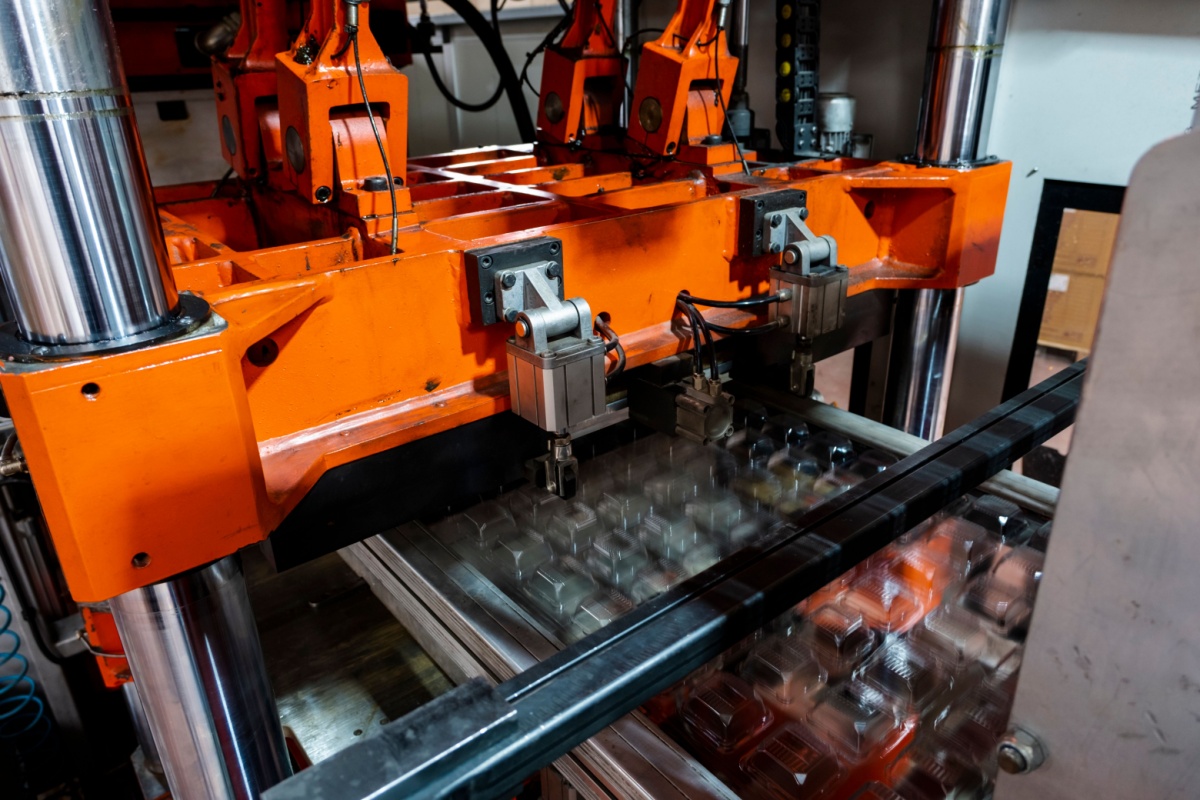

The Plastic Thermoforming Process

Thermoforming begins with a flat sheet of thermoplastic material. The sheet is heated until it reaches a temperature where it can be shaped without melting. Once pliable, it’s formed over a mold using vacuum pressure, mechanical force, or a combination of both. The result is a rigid or semi-rigid plastic component that holds its shape after cooling. The entire process can be tailored to create both thin-gauge products for packaging and thick-gauge items for industrial applications.

There are several variations of the thermoforming process, but two of the most common techniques are vacuum forming and plug-assist thermoforming.

Vacuum Forming

Vacuum forming is the most widely used thermoforming method due to its efficiency and simplicity. In this process, the heated plastic sheet is stretched over or into a mold, and a vacuum is applied to pull the material tightly against the mold’s surface. The vacuum removes air between the mold and the plastic, ensuring the sheet conforms to the exact shape and details of the mold. Once cooled, the formed part is trimmed to achieve the desired dimensions.

Vacuum forming is particularly well-suited for packaging solutions such as blister packs, clamshells, and trays, as it delivers consistent quality and clarity with minimal material waste. It’s also ideal for high-volume production runs where speed and uniformity are critical.

Plug-Assist Thermoforming

Plug-assist thermoforming is also known as mechanical forming because, during this process, a mechanical element is added to achieve greater precision. After the plastic sheet is heated, a plug is used to pre-stretch the material before vacuum pressure is applied. This ensures even wall thickness and improved material distribution across the finished part, which is especially important for deeper or more complex shapes.

Plug-assist thermoforming is a great option when you need enhanced dimensional accuracy, stronger packaging, or a smoother aesthetic appearance. It’s used on the majority of applications to assist the vacuum while distributing the material more evenly.

The Benefits of Thermoforming for Plastic Packaging

Thermoforming stands out as one of the most cost-effective and adaptable manufacturing methods in the plastic packaging industry. Of course, these aren’t the only benefits of using plastic thermoforming for your packaging products. Here’s a closer look at the advantages of this manufacturing process:

Cost-Effective Production

Compared to other plastic manufacturing techniques, such as injection molding, thermoforming requires significantly lower tooling costs and shorter setup times. This makes it ideal for both small production runs and large-scale manufacturing.

Additionally, design changes are easier and less expensive to implement, giving manufacturers greater flexibility when refining a product.

Design Flexibility

Plastic thermoforming offers virtually limitless design possibilities. Because the process can reproduce fine details and complex geometries, it’s easy to create packaging that perfectly fits your product while enhancing its visual appeal. Transparent materials can also be used to showcase products directly, making thermoformed packaging a powerful marketing tool as well as a functional one.

Lightweight Yet Durable

Thermoformed plastics are strong enough to protect products during handling and transportation but light enough to minimize shipping costs. This balance of strength and weight makes thermoforming a practical and sustainable solution across a variety of industries.

Efficient and Sustainable

Modern thermoforming processes are designed to minimize waste. For example, excess material trimmed from formed parts can be recycled and reused in future production runs. Many thermoformed materials are also recyclable themselves, aligning with growing environmental and sustainability goals.

Ideal for Branding

Because thermoforming molds can incorporate embossed logos, patterns, or text, it’s possible to brand packaging directly into the plastic. This creates a premium, professional finish that helps your products stand out on store shelves.

Common Types of Plastic Used in Thermoforming

The choice of plastic material is critical to the success of any thermoforming project, as each type of plastic influences the clarity, strength, flexibility, and environmental impact of the end product. For this reason, some of the most commonly used plastic materials for thermoforming include:

- PET (Polyethylene Terephthalate): Known for its excellent clarity, strength, and recyclability, PET is often used for food packaging and retail displays.

- PVC (Polyvinyl Chloride): A durable and versatile material, PVC provides great formability and resistance to impact, making it ideal for protective blisters and clamshells.

- HIPS (High Impact Polystyrene): HIPS offers good rigidity and impact resistance and is often used in food trays and medical packaging.

- Polypropylene (PP): This material is heat-resistant and flexible, making it suitable for reusable or microwavable packaging.

- HDPE (High-Density Polyethylene): This is a strong, impact-resistant, and chemical-resistant plastic ideal for industrial trays and material handling applications.

Partner With Munot Plastics for Custom Thermoforming Solutions

Since 1963, Munot Plastics has been at the forefront of thermoformed plastic packaging innovation. Our decades of experience have allowed us to serve an extensive range of industries with customized packaging solutions that meet both functional and aesthetic needs. Some of our most popular industries include:

- Food and Beverage

- Pharmaceutical and Medical

- Electronics

- Consumer Goods and Retail

- Automotive and Industrial

No matter your industry, our team combines cutting-edge thermoform tooling and manufacturing processes with decades of experience to design packaging that highlights your brand, protects your product, and delivers lasting value.

Contact us today to schedule a consultation and discover how our plastic thermoforming design services can bring your packaging to life.