Blister packaging combines clear plastic cavities with a printed backing card to deliver product protection, retail visibility, and tamper resistance. When thoughtfully designed, blister packs not only enhance shelf appeal but also reduce waste, improve logistics, and support today’s sustainability efforts.

Here, Munot Plastics will explore the steps on creating effective blister packaging that meets the expectations of today’s brands and consumers.

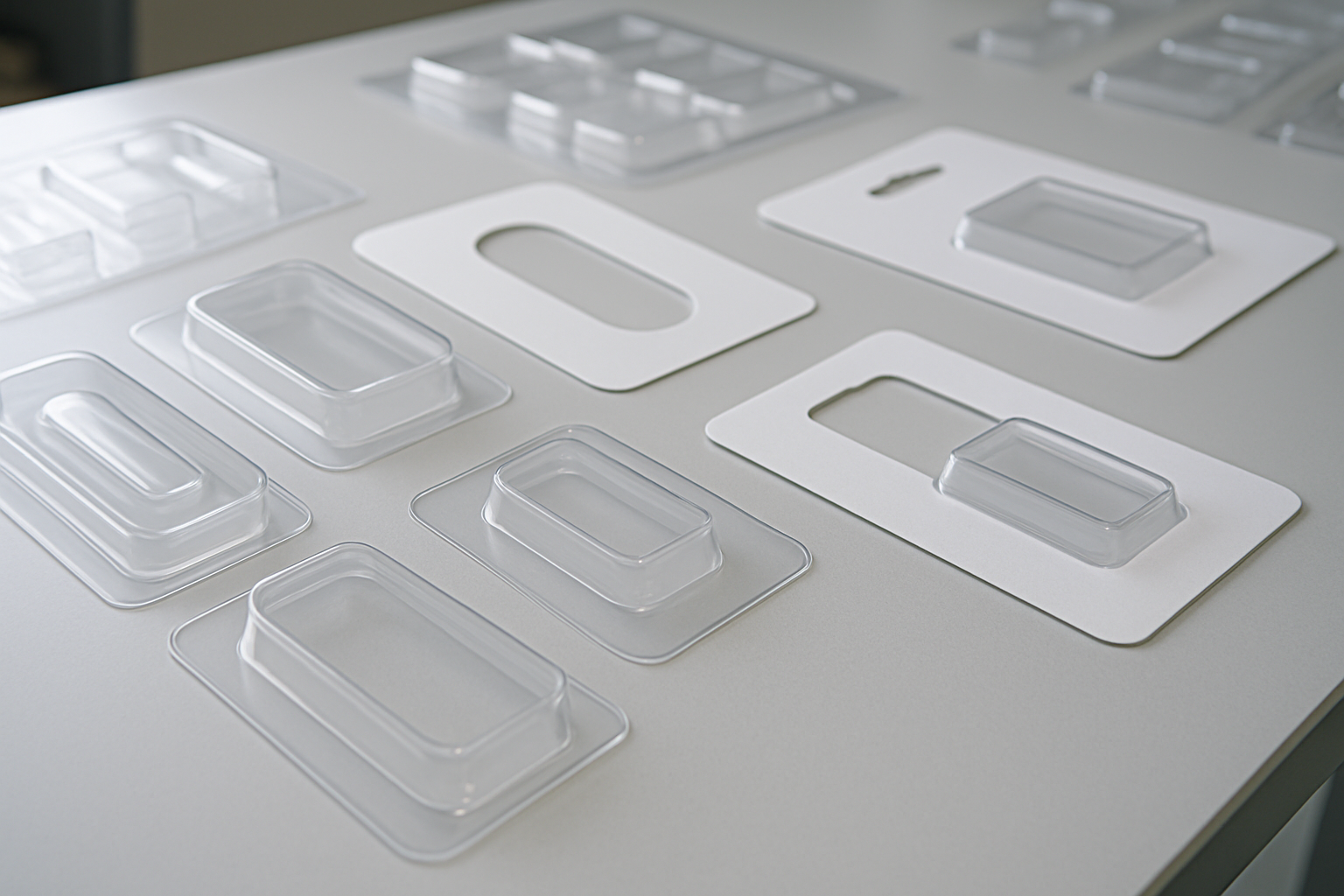

1. Start With Product Fit and Cavity Design

Every blister pack begins with an understanding of the product’s shape, fragility, and usage. Properly fitted packaging ensures the product stays in place, reduces breakage, and minimizes the need for additional protective inserts. Custom cavity design is an important step in preventing material waste and ensuring that the plastic forms cleanly with consistent wall thickness.

Our packaging design team uses their years of thermoforming expertise to create cavities that reflect both the aesthetic and functional goals of most businesses.

2. Choose the Right Material for Performance and Recycling

Material selection affects everything from clarity and barrier properties to environmental impact. Common materials used in blister packaging include:

- PET & RPET: Low cost, offers high clarity and strong recyclability, especially post-consumer recycled (PCR) RPET.

- PVC: Durable, but less sustainable and harder to recycle in some regions.

- HDPE and polycarbonate: Used for specialized applications where durability or resistance to chemicals is essential.

For companies with sustainability goals, RPET is increasingly the preferred choice. Incorporating recycled content helps reduce reliance on virgin materials and supports a closed-loop recycling system.

Learn more about material options on our Materials page.

3. Design With Sealing and Production in Mind

A good blister design isn't just about appearance. It must also perform well during manufacturing. Seal areas should allow at least 5 mm of width between cavities and card edges to ensure strong bonds without compromising the structural integrity of the packaging.

Blister cards are more than just backing—they’re part of the overall experience. Consider print quality, strength, and compatibility with your sealing process to ensure clean adhesion and a professional finish. Our packaging production services ensure your design translates smoothly to the production floor.

4. Improve Usability Without Sacrificing Security

Retail-ready blister packs must walk the line between theft resistance and consumer convenience. While tamper-evident features are important, overly sealed or rigid packages can frustrate users. Thoughtful features like tear notches, perforated openings, and peelable seals help improve accessibility without compromising safety or appearance.

The user experience is a vital part of how your brand is perceived. Packaging that’s too difficult to open often leads to customer complaints or returns.

5. Invest in Precision Thermoform Tooling

Even the best designs fall short if tooling isn’t accurate. Thermoform tooling defines the shape, fit, and finish of the blister cavity. Quality molds reduce variation, improve clarity, and help maintain consistent sealing during the forming cycle.

Tooling should be designed to support efficient material distribution, precise trim lines, and optimal forming temperature. At Munot Plastics, we engineer blister packaging using advanced tooling techniques that include custom cavity layout, plug-assist forming, and CNC-machined molds.

For more about how precision molds support performance, visit our Thermoform Tooling & Manufacturing page.

6. Build for Sustainability From the Start

Sustainability in blister packaging isn’t just about using recyclable materials—it’s about minimizing excess plastic, designing for recycling systems, and reducing waste throughout the lifecycle.

Key strategies include:

- Using RPET with post-consumer content

- Designing blister cavities that avoid unnecessary depth

- Reducing overall packaging dimensions to improve shipping efficiency

- Creating mono-material packs that avoid gluing incompatible plastics and paper together

Designing for disassembly—such as peel-off backing cards or easily separated trays—can further improve the recyclability of your packaging in consumer hands.

Sustainability also improves your standing with retailers and regulators. More and more retail businesses are requiring eco-conscious packaging, and blister packs designed for recyclability help brands align with those expectations.

7. Align Packaging With Brand Messaging

The clear front cavity of a blister pack gives shoppers instant visibility into the product. The backing card offers space for branding, instructions, safety warnings, and eco-certification icons. A cohesive layout can build trust and encourage purchase by clearly communicating value.

Consider QR codes that link to recycling information, social proof, or digital product instructions. These help declutter the physical card while keeping packaging informative and interactive.

Explore our full line of plastic blisters designed for retail environments across food, electronics, personal care, and more.

A Quick Design Checklist

|

Focus Area |

Best Practice |

|

Cavity Design |

Fit product tightly with even wall thickness |

|

Material Selection |

Choose RPET or PET for clarity and recyclability |

|

Seal Margins |

Maintain 5 mm for reliable sealing |

|

User Experience |

Add perforations, tabs, or peel features |

|

Tooling Precision |

Use CNC-machined molds for consistent forming |

|

Branding Space |

Design high-quality printed cards with clear messaging |

|

Eco Considerations |

Use PCR materials and reduce plastic depth where possible |

Learn More About Blister Packaging

Blister packaging continues to evolve, offering new ways to balance visibility, protection, and sustainability. To dive deeper into its advantages and origins, check out these additional resources:

- 6 Benefits of Blister Packaging

- Interesting Facts About Blister Packs Every Business Should Know

- Industries We Serve for applications in medical, food, and consumer goods

Frequently Asked Questions

What is the purpose of the blister cavity in packaging design?

The cavity in a blister pack isn’t just for looks—it’s carefully shaped to keep the product in place and visible. When it’s designed right, it prevents the item from moving around, getting damaged, or shifting during transport. Things like how deep the cavity is, how the walls are angled, and how evenly the plastic forms all need to match the size and weight of the product for a secure fit.

How do materials affect the performance and recyclability of blister packaging?

Material selection directly influences clarity, barrier properties, forming temperature, and recyclability. PET and RPET offer high transparency and better compatibility with recycling streams, especially when mono-material formats are used. Multi-material combinations can be harder to recycle and are being phased out in some regulatory environments.

Why is seal margin design important in blister packaging?

Seal margin design ensures structural integrity, tamper resistance, and reliable heat sealing. Insufficient margins can lead to weak seals, while overly large margins may result in material waste. Consistent seal width and compatible heat-seal coatings are essential for forming a secure bond between the plastic and backing material.

What role does plug-assist thermoforming play in blister packaging?

Plug-assist thermoforming adds an extra step where the plastic is gently pushed into shape before the vacuum takes over. This helps spread the material more evenly, which is especially useful for deep or complex shapes. The result is stronger, more consistent walls without needing extra plastic, just better control during forming.

How does thermoform tooling impact final packaging quality?

Thermoform tooling plays a big role in how a package looks and functions. It shapes everything from the cavity and edges to how cleanly the part is trimmed. When the tooling is done right, it helps keep each part consistent, speeds up production, and reduces waste. Details like venting, heat flow, trim design, and draft angles all come together to ensure the final package performs the way it should.

What are common design considerations for sustainability in blister packaging?

Sustainable blister packaging is all about using less material, choosing recycled plastics, and making the package easier to recycle. That might mean using RPET, keeping the cavities shallow, balancing the size of the card and blister, or making it easy to separate materials after use. It’s also important to design with local recycling rules in mind so the packaging can be properly handled when it’s thrown away.

What is wrap rage and how can it be prevented in blister packaging?

Wrap rage happens when packaging is so tough to open that it leaves people frustrated—or worse, injured. It’s often caused by tightly sealed, rigid plastic that requires scissors or a struggle to break into. To avoid that, designers can add simple features like tear notches, peel-away seals, or flexible hinges that make it easier to open while still keeping the product safe and secure.

How do blister packaging designs influence retail display and product visibility?

One of the main reasons blister packaging is so popular is because it lets shoppers see the product right through the clear plastic. That kind of visibility can encourage quick buying decisions and helps customers feel confident about what they’re getting. Getting the cavity aligned just right, reducing glare, and designing the backing card thoughtfully all play a role in making the product stand out on the shelf.

What are common regulatory or compliance considerations for blister packaging?

For products like medicine, food, or personal care items, blister packaging often has to meet specific regulations around safety, labeling, and tamper resistance. These rules can vary depending on the industry and where the product is sold, but they usually affect what materials are used, how the package is sealed, and what information needs to appear on the label.